- Stock: 3

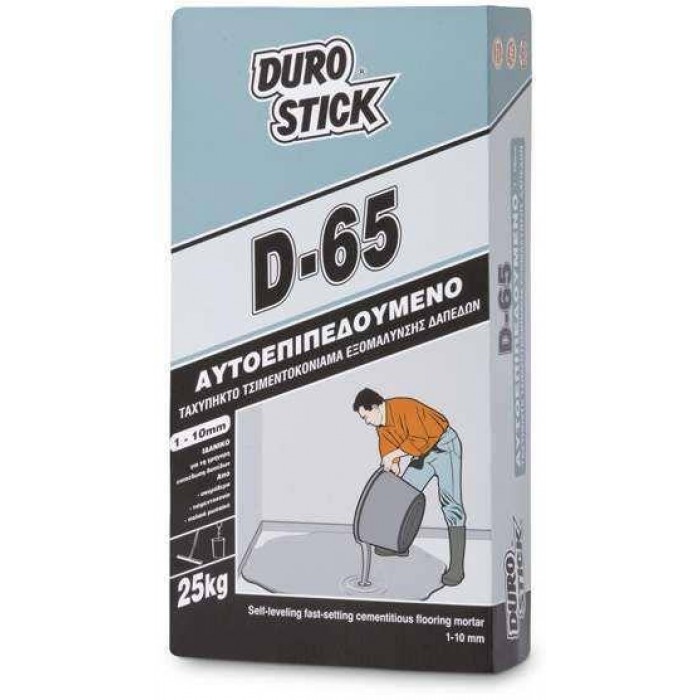

- Model: D-65 ΑΥΤΟΕΠΙΠΕΔΟΥΜΕΝΟ 25kgr

Self-leveling, fiber reinforced floor-leveling cement mortar for up to 10 mm thick, fast-setting and drying layers, with no shrinkage cracks. It is distinguished for its high abrasion resistance, compression, impact and disintegration, strong adhesion to any mineral substrate, as well as its excellent workability and pumpability. According to EN 13813 designated as C30-F6-A6fl.

The DUROSTICK D-65 is ideal for fast leveling of concrete, cement or old mosaic floors to be coated with adhesive marble, tile, plastic flooring, carpeting, parquet flooring etc. The smooth surface it offers allows it to remain as a final coating for basement floors, lofts, home warehouses and more.

Coating with HYDROSTOP FLOOR cementitious mortar after 24 hours ensures waterproofing and can therefore be applied to exterior surfaces.

1. Surface preparation

Clean the surfaces of dust, oil, grease and loose residues. The substrates must be primed with DUROSTICK acrylic emulsion D-20 diluted with water in a 1: 1 ratio prior to application of the material (D-20 consumption is 1 lt / 5 m2). The casting of the material follows before the emulsion has dried.

2. Application

Empty the DUROSTICK D-65 in pure water at a rate of 25 kg per 6-6.5 lt of water, stirring with a low speed drill, until a homogeneous mass without pellets is created. Spread the material from one corner of the floor, using a large rubber spatula (T) with a pole, helping to spread the material evenly across the floor. Release of any air bubbles is accomplished by a hard road cleaning broom or rolling pin.

3. Remarks

• For larger thickness applications up to 30mm use the new DUROSTICK D-64 self-leveling cement mortar.

• When starting to set, the material should not be used and will not be mixed with water again.

• The final surface must be protected from frost and high temperatures and moistened for the next 24 hours.

• The product after its full hardening is hazardous to health and the environment.